ABOUT

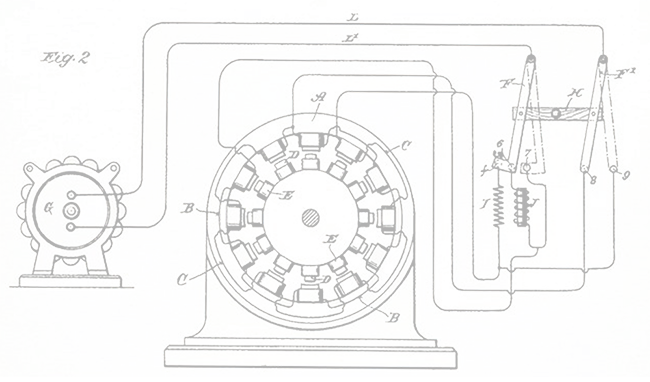

Turning Electronic Waste into a REEvolution.

Our motto is to create sustainability starting at the source...

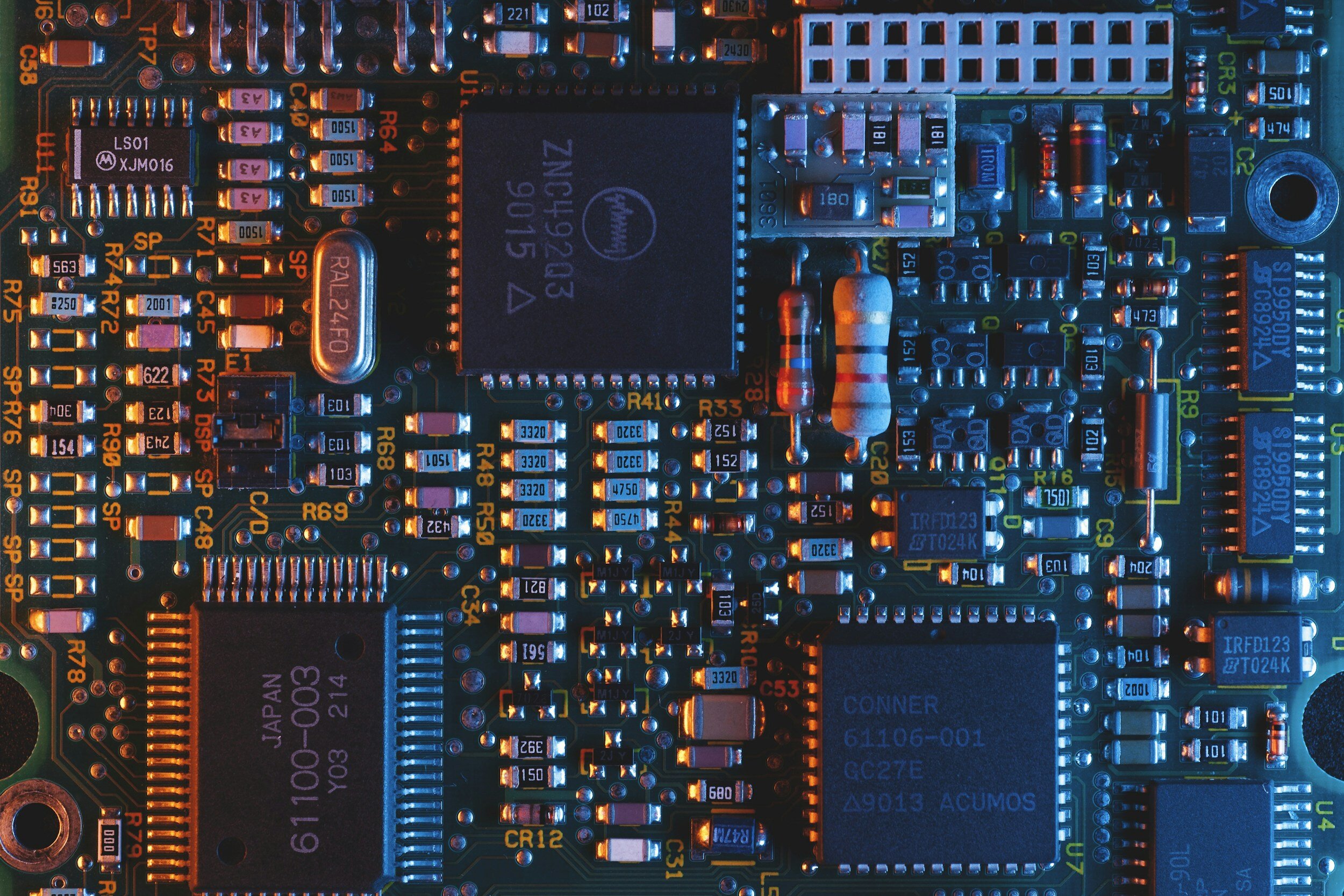

We recognize that supply chain concerns and availability of rare earth elements (REEs) are difficult issues for technology companies. These companies and their innovations can have significant positive impacts on the world-whether that be state-of-the-art consumer electronics, more efficient clean energy technologies, or improvements to the defense systems that protect us.

By creating a dependable, renewable, secure source of rare earth elements through recycling, REEcycle can reduce uncertainty for companies reliant on these materials.

How our story began

The REEcycle story began at the University of Houston in 2012. Our chemist, Dr. Samarasekere, became interested in the idea of developing a way to recycle rare earth elements after reading two Department of Energy (DOE) reports on critical materials for future energy use. In 2013, he discovered a chemical reaction that extracts 15 of the 17 rare earth elements found in discarded electronic waste. Our team began working to bring this innovative process to market. We concentrated on neodymium and dysprosium, the two that the DOE ranked highest in both importance to clean energy and in supply risk.

From 2014 to 2016, REEcycle won top honors and national awards at business plan competitions hosted by many top universities. In late 2014, REEcycle won all three top prizes at the U. S. Department of Energy’s National Clean Energy Prize Competition.

To date, we are the only recycling process that can safely and sustainably recover the highest amount of rare earth elements from electronic waste with the smallest environmental impact.

OUR TEAM

-

Mick McMullen

CHAIRMAN

-

Rasmus Gerdeman

CHIEF EXECUTIVE OFFICER & DIRECTOR

-

Casey McNeil

FOUNDER & ADVISOR

-

Justin Froneman

DIRECTOR

-

Luke Waier

HEAD OF SYSTEMS DEVELOPMENT

-

Dr. Pradeep Samarasekere

CHIEF CHEMIST & INVENTOR

OUR PROGRESS

REEcycle has now received both a Phase I and Phase II award from the National Science Foundation bringing total non-dilutive funding received to nearly $1.4 million.

Using this funding, REEcycle has been able to move forward with the build out of a demonstration plant facility intended to prove the feasibility of a full-scale, commercially viable REE recovery process.